OUR MANUFACTURING CAPABILITIES

From fabrication, to CNC machining, to testing and inspection, Specialty Machine delivers finished products on time, every time, to the highest standards of quality.

OUr Manufacturing services

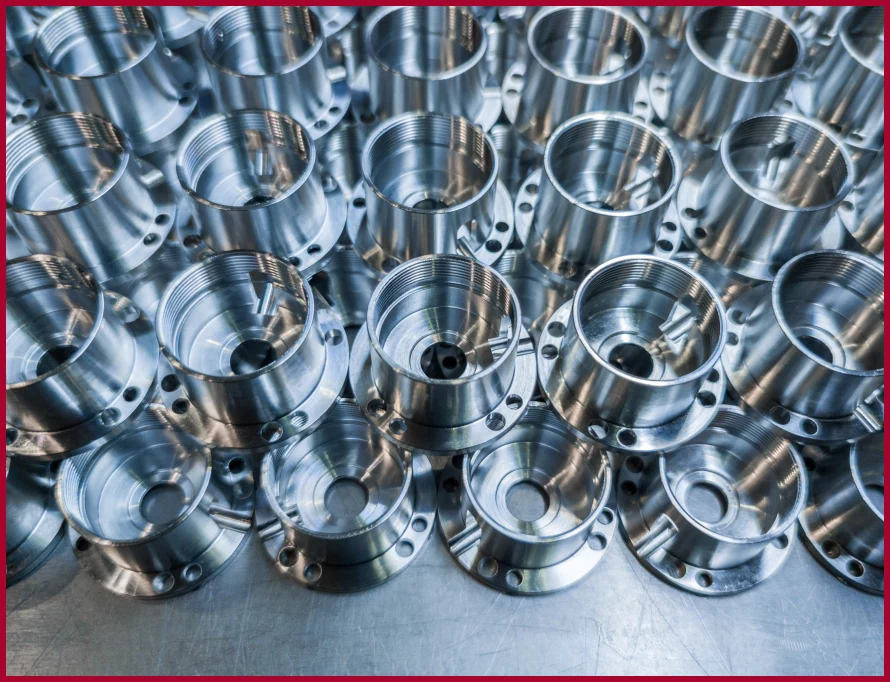

CNC Machining

Our CNC machining services leverage state-of-the-art equipment, including CNC lathes, vertical and horizontal mills, and metal presses, to produce precision components with tight tolerances and intricate geometries. From turning and boring cylindrical parts to milling complex 3D shapes, we handle a wide range of machining operations.

Our CNC Swiss turning capabilities enable us to produce small, intricate parts with extreme precision and complex features. Additionally, we offer EDM services, including sinker and plunger EDM, to create intricate shapes and cavities in hard metals or achieve high-speed hole drilling and precision shaping.

- CNC lathes

- CNC vertical mills

- CNC horizontal mills

- CNC metal presses

- CNC precision grinder

- CNC Swiss turning

- EDM – sinker

- EDM – plunger

Fabrication

Our fabrication services encompass a variety of metalworking techniques to transform raw materials into custom components and assemblies. We utilize sheet metal fabrication, brake press bending, and laser cutting to create precise enclosures, panels, and structural elements.

Our welding expertise spans various processes, including orbital welding for tubes and pipes, as well as MIG, TIG, and stick welding for joining diverse metals with strength and precision.

- Sheet metal

- Brake press

- High-precision cutting laser

- Orbital welder

- GMAW (MIG) welding

- GTAW (TIG) welding

- SMAW (Stick) welding

Manufacturing

Beyond core capabilities, we offer a range of value-added manufacturing services to support your project – from concept to completion.

Our rework and repair services ensure existing components meet specifications and perform optimally. We assist with material and product sourcing, procuring high-quality materials and components to meet your project’s specific needs. Our Oxygen Clean Room, certified to ISO14644-1/2, provides a controlled environment for sensitive assembly and packaging operations.

Additionally, we offer polishing services for achieving superior surface finishes, rapid prototype development for design validation, processing of model-based design only submissions, and comprehensive quality control to ensure all products meet or exceed your expectations.

- Rework and repair

- Quality control

- Oxygen clean room

- Polishing

- Prototype development

- Model-based design (MBD)

- Material and product sourcing

Testing & inspection

We maintain a rigorous quality assurance program, utilizing advanced testing and inspection equipment to verify the accuracy and integrity of your components. Our Coordinate Measuring Machines (CMMs) from Zeiss, as well as Brown & Sharpe, provide precise 3D inspection and dimensional analysis.

We conduct hydrostatic and vacuum testing for leak detection and pressure testing, and employ helium leak check for critical applications demanding ultra-low leak rates.

- CMM – Zeiss

- CMM – Brown & Sharpe

- Hydrostatic

- Ultra High Vacuum Helium Leak Check

Authorized Procurement

Beyond manufacturing expertise, we simplify your procurement process. As an authorized procurer, we leverage our extensive network and industry knowledge to source high-quality materials and components, ensuring your projects have the right parts at the right time.

Let us handle the complexities of procurement, allowing you to focus on your core business.

Our capabilities

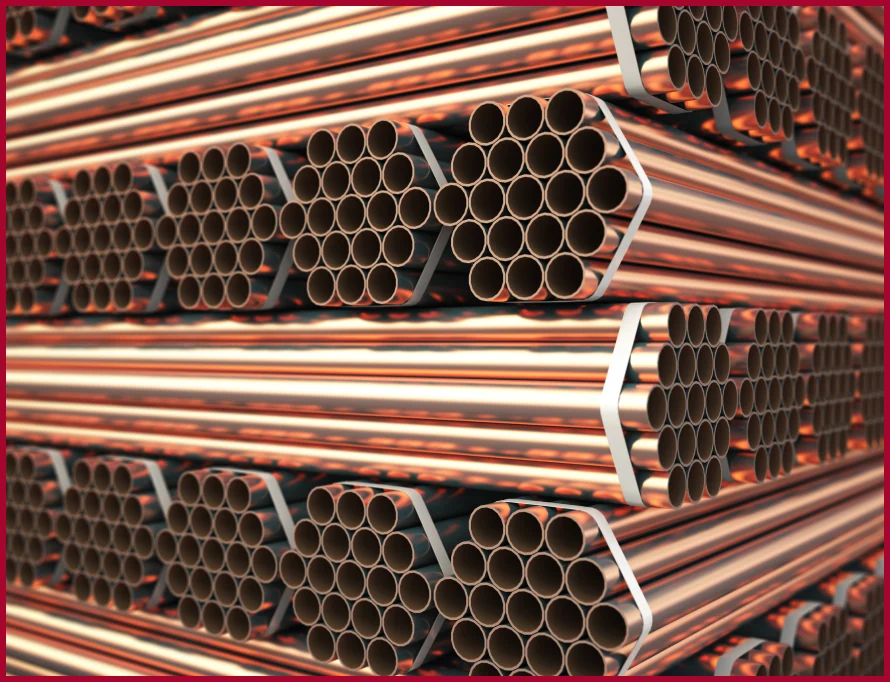

Materials we work with

We are not limited by material constraints. Our expertise extends to a wide range of metals, plastics, and composites, ensuring we can bring your most ambitious projects to life.

Whether you require precision machining of exotic alloys or welding of robust steel structures, we have the knowledge and equipment to deliver exceptional results.

Below are the most common materials we work with. If you don’t see your desired material below, just ask.